What is a capacitor…… like the the ones used with water bores?

A capacitor is a an electronic device that stores energy. In a single phase bore pump a start capacitor increases the starting torque for a short while and then brings the motor rotation up to a rate approaching the speed at which it will run the pump constantly. The bore start capacitor then drops out and a run capacitor takes over for energy efficient running of the pump.

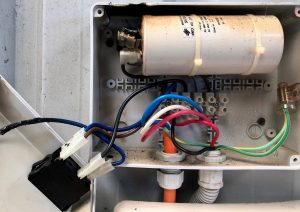

In most submersible pumps the capacitor is a dual start/run capacitor that does both. A capacitor used with a bore pump motor is normally perfectly cylindrical and about half the diameter of a soft drink can. It should not have black marks or be ruptured.

With a typical Perth submersible bore pump the capacitor, or condenser as it is sometimes referred to, is normally in a bore start box often mounted near the homes meter box. Remember bore start boxes are 240 volt and should only be accessed by a licensed electrician. We provide a fast mobile service all over Perth to replace burnt or blown bore pump capacitors.

The bore control box containing the start capacitor is not always next to the meter box as expected. We located this Lowara box in the roofspace.

The bore start box or bore control box is seen here bottom of pic. Not to be confused with the retic controller.

The submersible pumps with start boxes are known as “3 wire” motors (the wiring to the surface is 3 core and earth). Some submersible motors known as “2 wire” have the electronics and capacitor in the actual pump motor below ground and have 2 wires and an earth running up to the surface. 2 wire pump motors therefore do not have start boxes or easily replaceable start capacitors “3 wire” submersible motors are more common in Perth bores.

Capacitor Ratings.

The units of capacitance are labelled in microfarads (µF). Most Perth submersible garden bores will have a capacitor of between 35 and 60µF. A typical 1.1kw submersible pump will have a 40 or 45µF capacitor whilst a 1.5kw pump would usually have a 50µF capacitor.

Blown capacitor.

Sometimes capacitors blow. A capacitor blows for a few reasons but can include electricity supply surges or running during a nearby lightning strike. Capacitors can also overheat. With long term use over many years capacitance can also drop which can prevent the pump motor to start or causes it to run at a reduced speed.

A faulty capacitor may simply become swollen or uneven in shape. The ends may become distended or bowed out. More commonly though it will “blow” causing the electrolyte to leak out and often make a big charred and smelly mess. It is important that after a blown capacitor is replaced that the pump windings are tested and results compared against manufacturers specifications.

Will using a higher Microfarad (µF) capacitor provide more starting torque?

When replacing a water bore pump capacitor it is important it is replaced with the correct type and size. Is it a dual start /run version/capacitor? Will using a higher Microfarad (µF) capacitor provide more starting torque? Well yes but not without negatives including higher motor run temperatures, shorter life and greater electricity consumption. It’s a balancing act that the bore pump manufacturer has thought long and hard about so always use the correct rating.

Always replace the capacitor with the same spec and size. This one needs a 45 microfarad ) not the 60µF pictured alongside.

Bore Electrical Repairs and Service around Perth

A start capacitor on a bore should only be replaced by a licensed electrician experience in working with water bores. The electrician would typically also meggar test the bore motor to check the health of the windings and other readings at the same time. Call Virgin Bores 0n 9246 0111 to book a repair anywhere in the Perth greater metropolitan area. You can also request a bore repair online and we will ring you back to arrange a suitable time.